Businesses with a successful corporate recycling program have reduced their waste costs by up to 50%, while lowering their environmental impact. Beyond cost savings, recycling options generally add a revenue stream for companies, among other benefits of a recycling program including customer trust and reduction of overconsumption and energy usage.

For a corporate recycling program to be efficient, scalable and profitable, companies need the proper commercial recycling equipment. Read below to see what you need to get started and how it pays off.

The Core Recycling Equipment Every Business Needs

#1 Commercial Recycling Bins

For businesses with small-scale waste generation or office recycling, gaylord boxes, wheeled containers, office desk bins or recycling bins within a breakroom or common area are ideal solutions. These bins separate materials, so waste doesn’t end up in a landfill due to contamination. If bins are overflowing or constantly being picked up, and total waste generation exceeds more than a few cubic yards, it might be time to consider a container.

#2 Commercial Recycling Containers

Larger than recycling bins or gaylord boxes, commercial recycling containers such as a front-load or an open-top roll-off container are designed for higher volume, steady recycling streams. Different materials can be kept in separate containers, which is helpful for manufacturers, distribution centers or other industrial operations that produce high volumes of a single material. These containers can hold more material onsite, reducing pickup frequency and overall waste costs.

#3 Commercial Recycling Compactors

If a company has its containers hauled multiple times a week, a commercial recycling compactor would be the next logical step in onsite recycling equipment. A commercial recycling compactor is ideal for businesses who generate less than 20 tons of recycled materials per month.

Compactors improve site cleanliness and storage by turning bulky materials into manageable cubes or bales. By reducing the volume of waste and recyclables, compacted materials cut down on waste collection costs and emissions with less hauls. There are two main types of compactors:

- Self-contained compactors combine the compactor and container as one unit, an ideal solution for keeping wet or food-based waste sealed to prevent leaks or odors.

- Breakaway compactors work well for dry waste such as standard paper, cardboard or packaging materials.

#4 Balers

A must-have for businesses generating more than 10 tons of recyclables per month, balers compress and bind paper, cardboard, plastics and metals into compact bales for resale. By reducing the volume of materials, these baled items are easier to handle and process, streamlining the recycling process and helping to lower emissions from transportation and handling.

#5 Industrial Shredders

Companies use industrial shredders for two main reasons: to securely destroy confidential or sensitive business documents and safely and efficiently reduce the material volume of large-scale, dense or irregular materials that cannot be processed by a compactor or baler.

Many companies have shredding equipment onsite to handle confidential document waste that is collected and disposed of responsibly. Industrial shredders can be used by large printing companies to shred long sheets of printed material or big overruns that are difficult to bale. Box plants are another type of business that may utilize industrial-size shredding equipment.

Companies utilizing these five essential recycling equipment options can load recyclables more efficiently, reducing pickups and trips — which helps cut costs and lessen environmental impact. These tools are foundational to any commercial recycling system.

Equipment Strategy, Maintenance & Support Services

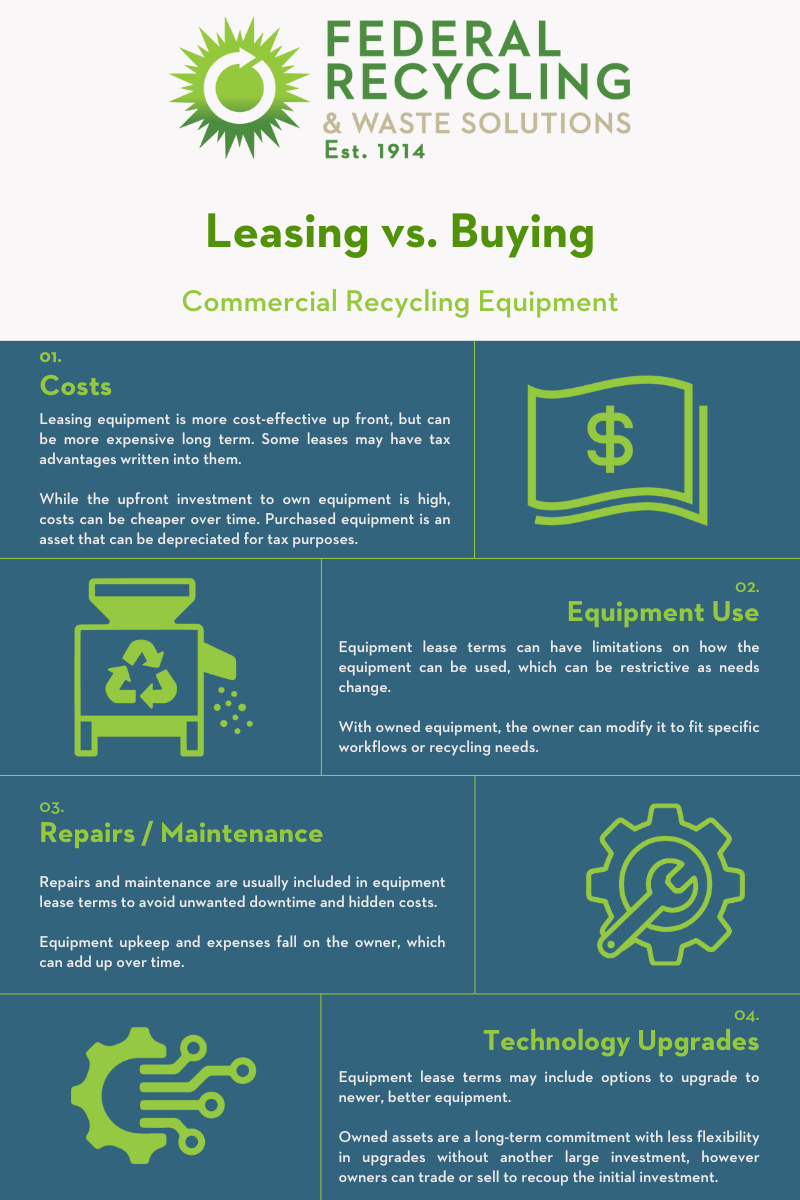

Leasing vs. Buying Equipment

Leasing commercial recycling equipment is beneficial for companies to invest in technology without a large upfront financial commitment.

- Many companies combine service, repairs and general maintenance in their leasing contracts to reduce downtime and hidden costs, with options to upgrade to newer models at the end of the agreement.

- Some leases might provide tax advantages, serving as tax-deductible operational expenses.

With those advantages in mind, it’s also important to consider the drawbacks of leasing equipment.

- A typical lease can span multiple years, which can be restrictive should your recycling needs change overtime and lead to higher costs over time.

- Certain usage limitations may be imposed, restricting the flexibility of how the equipment can be used.

For those looking for a permanent solution, buying equipment provides more flexibility for corporate recycling programs.

- Purchased equipment is a company asset that can be depreciated for tax purposes. Depending on location, companies may be eligible for depreciation deductions or green equipment tax credits.

- With complete ownership, companies can modify their equipment to fit specific workflows or recycling needs to stay aligned with sustainability efforts.

- With proper care and maintenance, purchasing equipment is also cost effective long-term.

- Owned equipment can be sold or traded in to help recoup some of the initial investment.

However, it’s also important to evaluate the potential limitations of purchasing equipment.

- Purchasing equipment requires a higher upfront cost that can tie up significant capital.

- All equipment upkeep and related expenses fall on the owner, which can add up over time.

- Due to the significant investment, companies are tied to their purchased equipment assets for the long term, which provides less flexibility to upgrade technology without another large investment.

To ensure your equipment strategy is aligned with your sustainability goals, Federal Recycling offers customized equipment buying and leasing programs. For more information on these commercial recycling services, click here.

Equipment Maintenance & Support Services

With proper maintenance and support, your recycling equipment can last for many years. Preventive maintenance avoids costly breakdowns and downtime, ensuring your recycling program is running smoothly. Federal Recycling offers comprehensive repair services and maintenance plans to ensure the success of your recycling program.

Set Your Program Up for Success

A successful commercial recycling program requires time, effort and the right tools and resources, including commercial recycling equipment. With a well-planned approach, your business can reduce waste, cut costs and boost sustainability efforts. Our team provides expert guidance every step of the way and the equipment solutions to ensure your program runs smoothly.

Get started today by contacting us.